FracTech has been an independent testing resource for the global hydraulic fracturing industry since 1993. In addition to supporting operators to help select the optimum fluids and proppant for wells, FracTech has been active in improving the testing protocols. Some examples are given below:

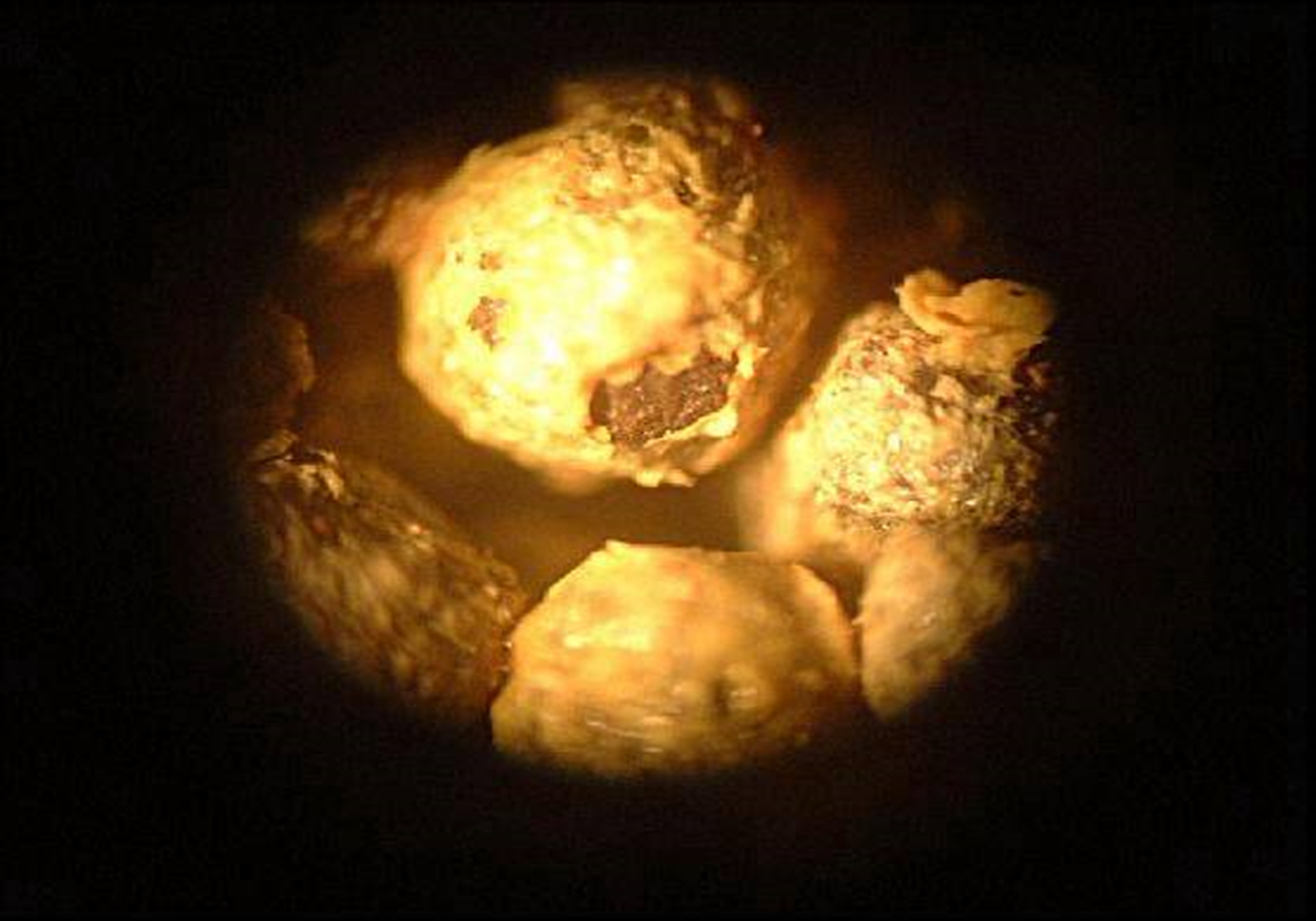

Proppant Flowback Qualification

Preventing proppant flowback is key to many offshore fracturing programs and FracTech commercialized the industry's first specific flowback testing apparatus. An early significant finding was the concept of resin detachment where the resin coating detaches from the ceramic substrate during pack deconsolidation rather then the inter proppant contact meniscus failing (see image above). Understanding the mode of failure helps operators and developers improve product performance while maintaining tight cost controls.

Realistic Fracture Conductivity & Multiphase

The founder of FracTech performed some of the first realistic multiphase flow test simulations for the industry and provided much more realistic data for use in the Southern North Sea BP development at the time. This approach informs much of our specialist testing today and spurred the development of shale application testing with packs at 0.1lb/ft2 and less. This data has been published and represents much of the limited narrow fracture data available to the industry.

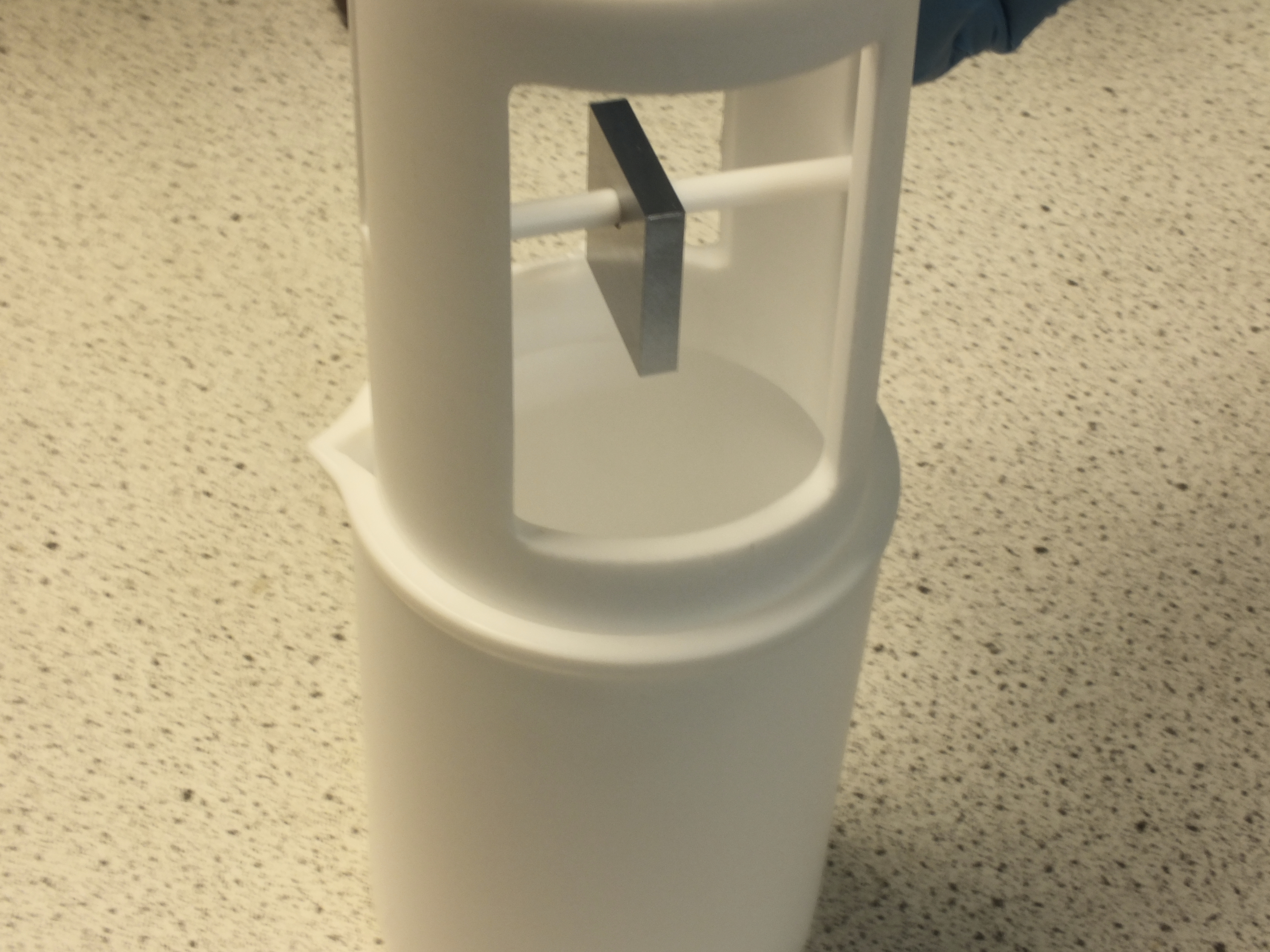

Sealing Molds for Conductivity Cells

FracTech developed molds early on to provide a more consistent and reliable seal between the core wafer and the cell, considerably improving repeatability. These are now in widespread use and FracTech still manufactures them.

Repeatability Testing

With a strong theoretical physics background to our work, we are aware that the certainty in a measurement that is unrepeated is zero. Repeating tests is essential to statistical analysis. FracTech has pushed cost viable repeat testing in the industry to enable proper data confidences to be determined.

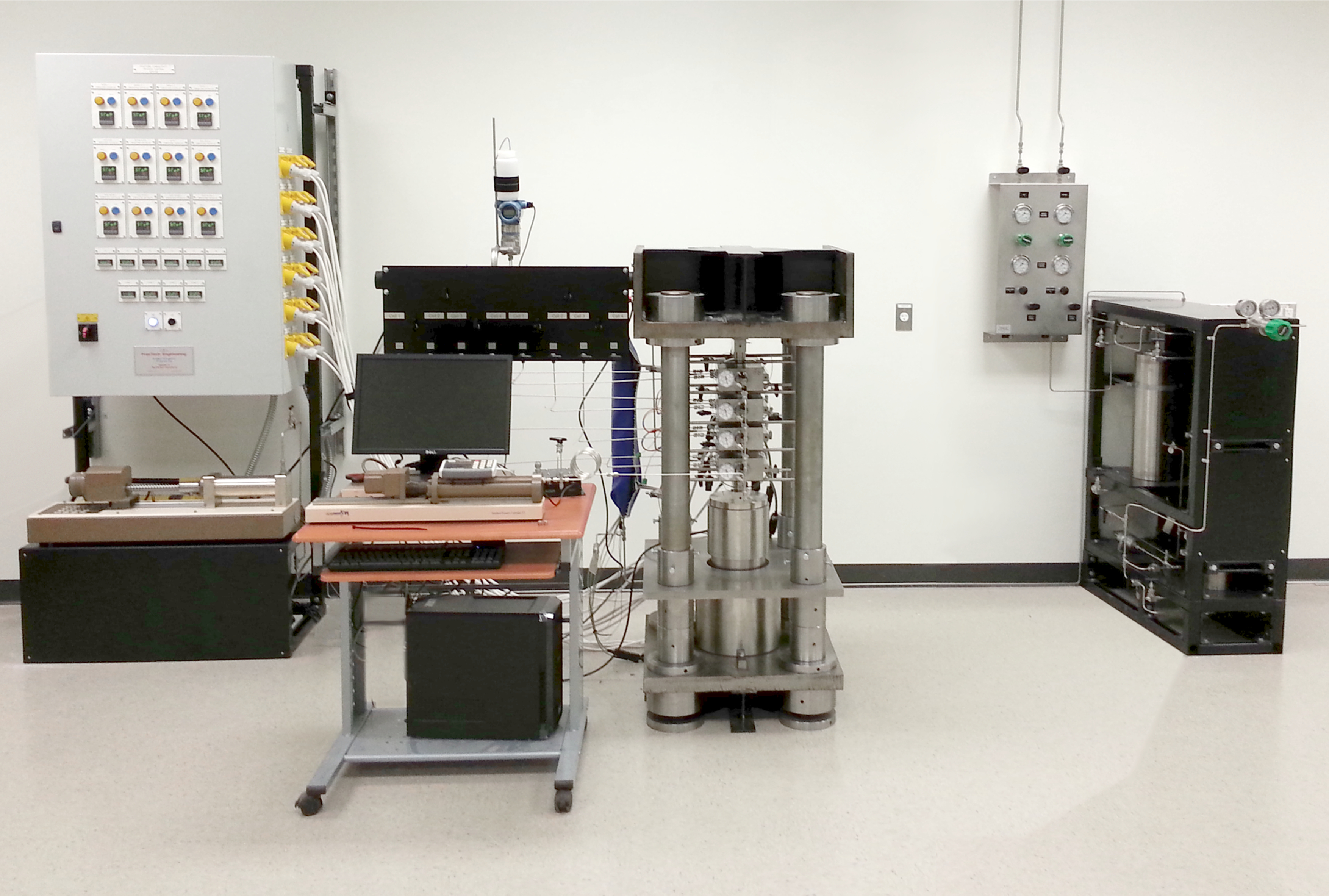

Equipment

8 standard hydraulic presses with up to 20 conductivity cells

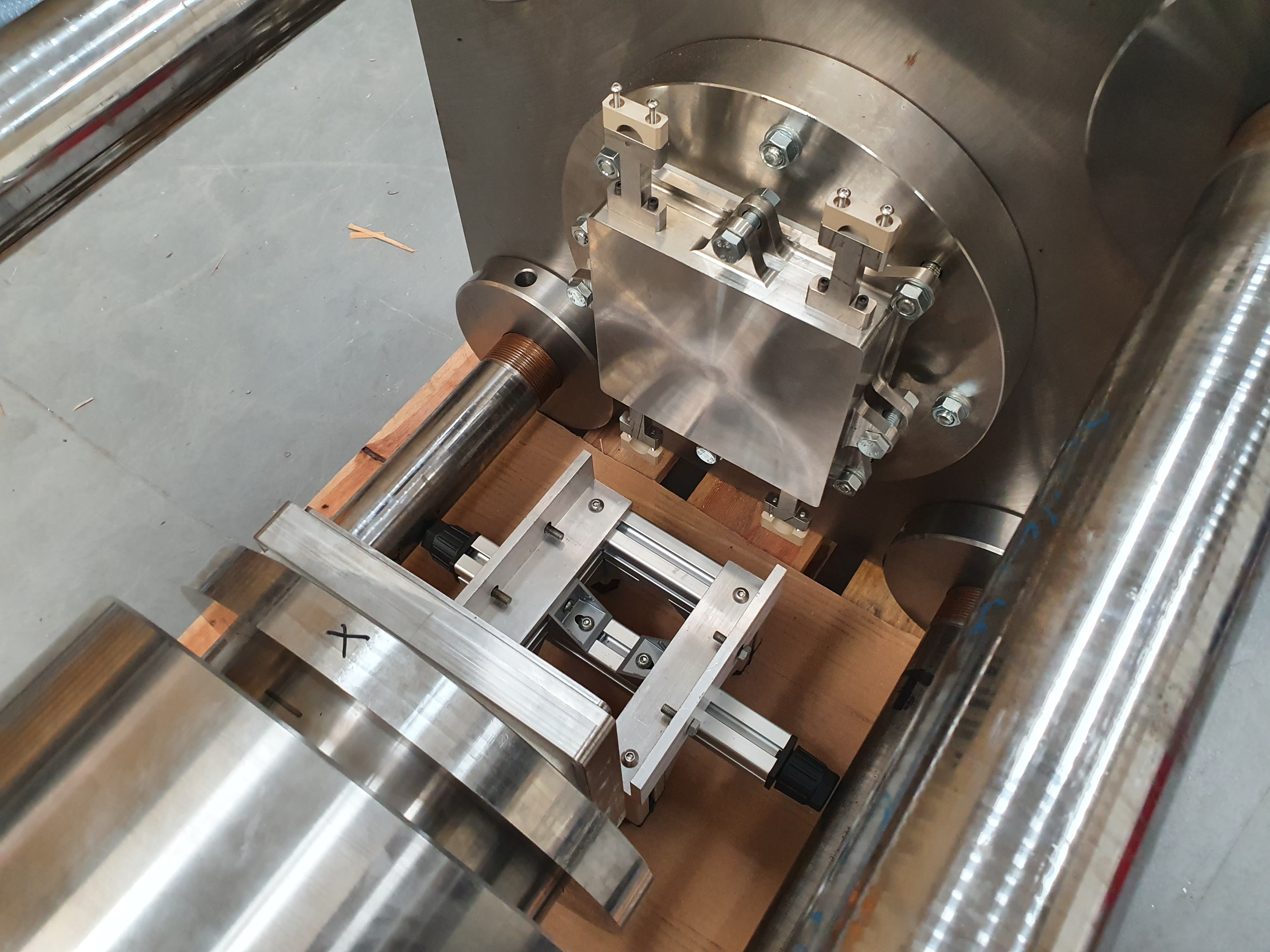

30,000psi ultra high stress load frame and special conductivity cells for Deep Water

Extended conductivity cells for fracturing fluid leak off and regained conductivity

Non-Darcy gas flow determination apparatus

Multi phase flow (oil, brine, gas) conductivity loop

1 vertical 200 tonne press for flowback testing with two 41 sq.inch flowback cells

20' by 4.5' slot for proppant transport with 7 way video monitoring and 400lt/min pumps; solids addition screw pumps

Grace rheometers to 400F

Pipe rheometer for friction reduction and shear loop for fluid shear degradation

5000psi, 175F corrosion inhibition test rig

Acid rotating disc equipment

Etched acid conductivity cell